How Pharmaceutical Onshoring is Reshaping Digital Health

The pharmaceutical industry is undergoing a fundamental reshaping as major manufacturers accelerate their transition to US-based production facilities. This shift, driven by trade policy changes and supply chain vulnerabilities, could have significant implications for healthcare technology infrastructure as companies digitise newly established domestic operations.

According to KPMG and PwC data, healthcare M&A activity could experience substantial growth throughout 2026, with 73% of life sciences executives anticipating increased deal activity. This manufacturing migration represents a convergence of evolving trade regulations, regulatory certainty requirements and the vulnerabilities exposed by recent global supply chain disruptions.

Tariff implementation in early 2025 has accelerated decision-making timelines for pharmaceutical companies reassessing their global manufacturing networks. On 13 January 2025, Johnson & Johnson entered a voluntary arrangement with the Trump administration, committing to reduce medication costs in return for expanded domestic operations. The agreement positions J&J within the "most-favoured-nation" pricing framework and secures exemption from recently implemented tariffs, conditional upon ongoing investment in US manufacturing.

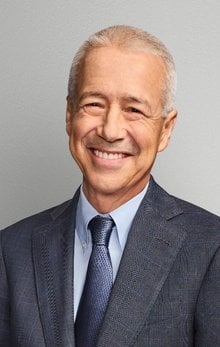

"Today's agreement shows that when the public and private sectors work together towards shared goals, we can deliver real results for patients and the US economy," explains Joaquin Duato, Chairman and CEO of Johnson & Johnson.

J&J is one of multiple major pharmaceutical companies pursuing this approach. AbbVie became the 16th significant drugmaker to finalise a comparable agreement, pledging US$100bn towards US research and development and manufacturing throughout the next decade.

"AbbVie's mission is to make a remarkable impact for the patients we serve around the world through our innovative medicines," says Robert Michael, Chairman and CEO at AbbVie.

Digital infrastructure requirements expand

The transition towards US manufacturing extends beyond tariff considerations to encompass operational resilience and digital transformation. Biopharma companies are increasingly requesting dual-site redundancy across different geographic territories to minimise supply disruption risks, creating demand for integrated digital monitoring systems.

Domestic manufacturing could potentially streamline Food and Drug Administration validation processes and quality oversight, offering competitive advantages in regulatory approval timelines. This regulatory efficiency relies heavily on digital documentation systems and real-time data connectivity between production facilities and regulatory bodies.

Celltrion has purchased a former Eli Lilly site in New Jersey, with plans to double production capacity by 2030 to strengthen its US supply infrastructure. Investment is also concentrating on high-growth therapeutic categories, with BD (Becton, Dickinson and Company) announcing a US$110m investment in Nebraska on 13 January 2025 to manufacture advanced glass prefillable syringes, responding to increased demand for GLP-1 weight-loss treatments.

Novartis provides an example of this regionalisation trend with digital implications. On 9 January 2025, the company revealed its fourth US radioligand therapy manufacturing facility in Winter Park, Florida, forming part of a wider US$23bn investment programme in the country.

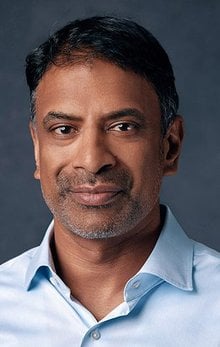

"Building this new facility in Florida marks an important step in fulfilling the promise of RLT for patients," adds Vas Narasimhan, CEO of Novartis. "Radioligand therapy has fundamentally changed how we approach certain cancers, and our growing US manufacturing network ensures we can continue to deliver these critical medicines with speed and reliability to patients who need them."

Implementation timeline considerations

The transition to US-based manufacturing capacity will not occur immediately. Industry specialists project a three-to-four-year timeframe for substantial capacity modifications, reflecting extended lead times for facility development, equipment validation and regulatory approval procedures.

Throughout 2026, the pharmaceutical sector is undergoing structural change. The model of geographically dispersed global logistics is transitioning towards a framework where patient affordability and domestic manufacturing capability are elevated alongside innovation.

This shift could require healthcare organisations to invest in digital infrastructure capable of supporting distributed manufacturing networks, real-time quality monitoring and integrated supply chain visibility systems that connect domestic production facilities with healthcare providers and patients.

The convergence of manufacturing regionalisation and digital transformation represents a fundamental evolution in pharmaceutical operations, with implications extending across the entire healthcare technology ecosystem.